Developing software for consumer electronics is an entirely different ball game from building digital-only products. It’s not just about writing clean code or shipping features fast-it’s about harmonizing embedded software with evolving hardware, unpredictable supply chains, industrial design tweaks, regulatory constraints, and a rapidly approaching mass production date.

In this landscape, seemingly small oversights-like skipping early diagnostic tools or assuming hardware won’t change-often lead to major delays, budget overshoots, or unstable post-release performance.

So how do experienced teams keep everything aligned and flowing? What separates the projects that launch on time and scale smoothly from those stuck in rework hell?

This post distills the less-obvious, high-impact tactics we’ve refined over years of managing CE software projects-from wearables and audio gear to gaming peripherals and connected devices.

Why CE Software Projects Are a Different Beast

In theory, managing software for consumer electronics (CE) should follow the familiar rituals of product development: define scope, assemble the right team, sprint, iterate, deliver. But in practice, it’s rarely that clean.

Why? Because CE software operates at the intersection of volatile hardware revisions, compressed production cycles, external certifications, and post-market expectations-all of which conspire to stress-test even the most battle-hardened project plan.

Unlike standalone apps or SaaS platforms, CE software:

- Must adapt to evolving electrical and mechanical realities-not just changing user stories.

- Is tightly bound to factory timelines, tooling constraints, and production windows.

- Needs to anticipate edge-case behaviors in unpredictable real-world environments.

In short, it’s not just about writing good code-it’s about orchestrating a multi-dimensional product ecosystem, where misaligned assumptions can delay launches or spike costs.

At Developex, we’ve spent over 15 years supporting CE brands-from audio systems and gaming peripherals to smart IoT devices-and we’ve seen firsthand how subtle planning gaps can snowball into launch-day chaos.

Key Strategies for Consumer Electronics Success

To succeed in the competitive world of consumer electronics, it’s essential to go beyond just creating a functional product. This guide outlines key strategies for building durable, adaptable, and scalable devices that can thrive in the real world, from the first prototype to mass production and beyond.

1. Think Beyond the MVP

When developing software for consumer electronics, a “working MVP” isn’t the finish line – it’s just the entry ticket. Your MVP needs to withstand the messiness of the real world – firmware decay, user misuse, signal interference, and post-launch support issues. These risks should be addressed early, not deferred.

A resilient MVP means building a technical foundation that supports diagnostics, remote updates, and graceful failure recovery. These capabilities are far cheaper to implement early than to retrofit after launch – especially once devices are already in users’ hands.

Equally important is how you track progress toward this MVP. Tie milestones to tangible deliverables – like code builds, demos, and test results – not just hours logged or status meetings. This helps you identify risks early, make smarter decisions, and keep control over the development process.

Pro Insight: Think of your MVP not as a launch pad but as the foundation of a durable product architecture – one that supports updates, diagnostics, and recovery. Building these capabilities early costs far less than trying to fix them when your device is already on shelves.

2. Secure Full Ownership of Your Code

Your ability to iterate quickly and respond to bugs or market feedback hinges on one critical factor: whether your team actually owns the codebase. Many hardware manufacturers offer “full-service” firmware development – but retain control over the code, locking you into long-term dependency and limiting your ability to innovate or react. While in the short term or standalone projects it might seem an option and can be a less time or budget-consuming choice, in the long term and especially for scaling and expanding products, it may be a tricky situation.

Ownership isn’t just about access – it’s about freedom. When your team has direct control, you can switch vendors, onboard experts, or adapt the firmware stack without delays or contractual roadblocks.

Pro Insight: Lack of code ownership turns your MVP into a black box. If you want flexibility, future-proofing, and better vendor leverage, make code access and IP terms a priority from day one.

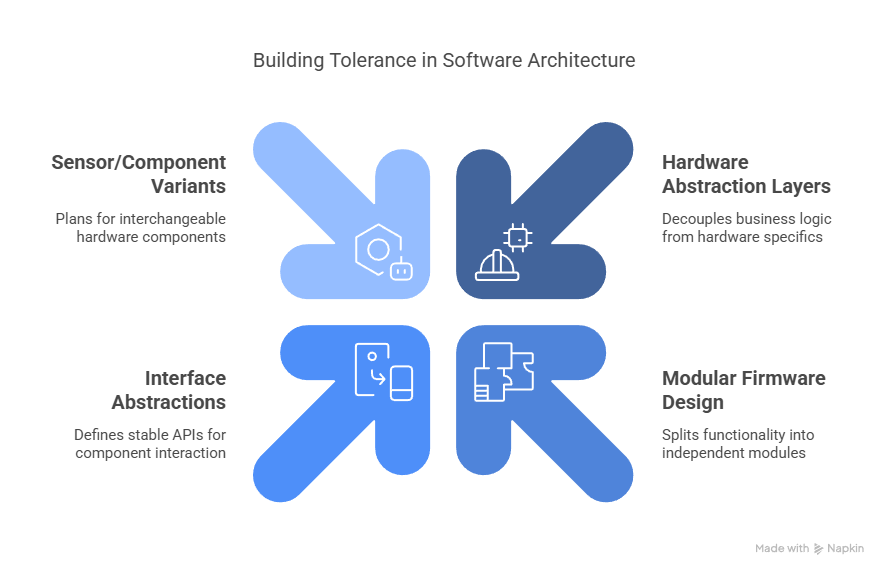

3. Design for Hardware Change Tolerance

Hardware never stays still. Between early prototypes and mass production, revisions are inevitable – a new sensor, a last-minute layout tweak, or even a different MCU due to supply issues. To avoid delays, regressions, or costly rewrites, ensure your software is flexible and can adapt to these changes seamlessly.

Architect flexibility from day one by using hardware abstraction layers (HALs) to decouple your software from specific hardware components. This way, hardware changes can be accommodated with minimal disruption, allowing your firmware to evolve without costly rewrites.

Pro Insight: Modularity isn’t just a coding pattern – it’s a risk mitigation strategy. A modular system lets you iterate quickly and minimize disruptions when hardware changes occur.

4. Invest in Business Analysis and Documentation

Long-term success in consumer electronics often hinges on thorough business analysis and clear documentation. As the complexity of your product grows, so does the need for comprehensive Functional Requirements Documents (FRD), System Requirements Documents (SRD) and and a well-structured PRD Template for Electronics Projects. These documents serve as the blueprint for all technical work, ensuring alignment between development teams, stakeholders, and contractors.

By investing time in these documents, you’ll avoid miscommunications and scope creep, ensuring your project stays on track and within budget, especially in large-scale projects. Business analysts (BAs) should work closely with product teams to outline detailed requirements before development begins.

Pro Insight: High-quality documentation and early BA involvement are essential for avoiding misunderstandings and ensuring a successful long-term project.

5. Automate Real Hardware Testing Early

Real-world bugs often reveal themselves only when software runs on actual hardware. Power fluctuations, unstable clocks, or noisy signals rarely appear in simulations. To catch these issues early, integrate hardware-in-the-loop (HIL) testing as soon as possible.

Automated regression tests, stress testing, and edge case simulations will help uncover issues before they escalate. This approach ensures that every firmware build is robust, reliable, and capable of handling real-world stressors. Additionally, conducting early and continuous testing means you can act on bugs immediately, preventing delays later in the project.

Pro Insight: Hardware-backed automation doesn’t need to be expensive. A simple test jig, some relays, and a logging script can uncover weeks of hidden risk-before you’re on the hook for a firmware recall.

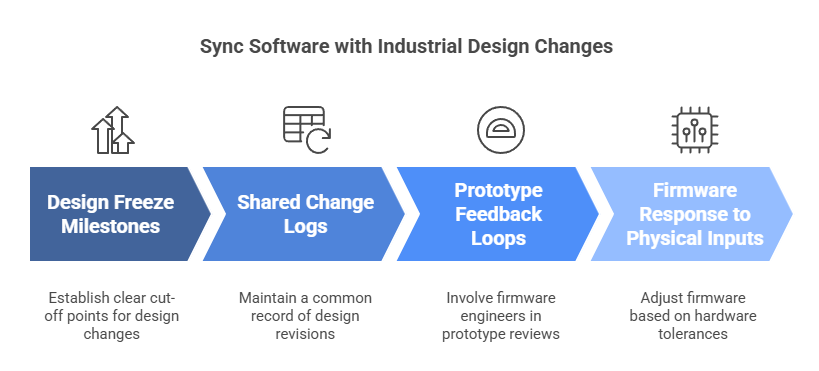

6. Sync Software with Industrial Design Changes

Firmware can break in subtle ways when industrial design evolves mid-development. A shifted button, new casing material, or minor sensor relocation can affect software behavior. To avoid late-stage surprises, ensure that the software and design teams collaborate from the very start. Firmware engineers should be involved in reviewing early prototypes – not just final models.

Establish design freeze milestones to prevent unnecessary disruptions late in the project. A shared log of design updates ensures that firmware is prepared for any changes that may affect functionality, minimizing surprises during Quality Assurance ( QA ) or post-launch.

Pro Insight: Treat design and firmware as a co-evolving system. This mindset prevents misalignments that often surface only in late QA or, worse, in customer hands.

7. Iterate and Gather Feedback

An iterative approach is critical for success in consumer electronics. Feature flags and modular firmware design allow you to implement incremental updates and test new features in the field without exposing end users to unfinished work. Make sure to gather detailed feedback after every delivery of software or firmware to ensure it aligns with user needs.

In the beta testing phase, consider involving third-party testers to get unbiased feedback on the product’s performance and usability. This approach helps refine the product before launch and ensures that it meets the expectations of real users, not just internal stakeholders.

Pro Insight: Iterative feedback loops and beta testing with external testers will help you catch problems early and ensure your product performs well in real-world conditions.

8. Include OTA and Security from Day One

Over-the-air (OTA) updates aren’t optional – they’re a fundamental part of maintaining control over your product once it’s in the field. Secure bootloaders, encryption, and signed firmware should be incorporated from the start, not as afterthoughts. Retrofitting OTA infrastructure is risky and brittle.

Ensure that your firmware includes secure update capabilities and a system for safely rolling back updates in case of issues. Security and updateability are core systems that must be planned for early, to protect your device and ensure that it remains resilient post-launch.

Pro Insight: Treat OTA as a core system service, not a future feature. It’s the only way to maintain control, stability, and trust after deployment.

9. Plan for Manufacturing Diagnostics

Manufacturing doesn’t just assemble your device – it validates it at speed, under pressure, and at scale. And yet, software teams often overlook the firmware tooling required for testing devices on the production line until it’s almost too late.

To avoid costly delays and returns, your firmware must include dedicated diagnostics and factory test modes designed to operate in high-throughput environments. These aren’t just engineering conveniences-they’re essential for a scalable, efficient production process.

Here’s what smart teams build in from the start:

- Production Test Mode: A streamlined firmware state that bypasses normal boot logic and enables sensor checks, input/output tests, and core component validation in seconds.

- Quick Logging Hooks: Minimal, structured logs optimized for factory equipment-think USB outputs, LED flashes, or serial data for pass/fail signals.

- Built-In Self-Tests (BISTs): Lightweight routines that verify key hardware functions with minimal overhead, useful for both production and field service diagnostics.

- Remote Configuration Options: Ability to flash test firmware and return to production firmware cleanly, without reprogramming or manual intervention.

Integrating these capabilities into the development pipeline-rather than bolting them on in the final weeks-ensures a smoother ramp to mass production and fewer surprises on the factory floor.

Pro Insight: If your firmware can’t help test your hardware at scale, it’s not done. Manufacturing support is as critical as any feature-and should evolve alongside the main product firmware.

10. Bring in a team with firmware experience

Embedded development is not just about programming – it requires deep interaction with hardware, precise timing, low-level optimization, and real-world device constraints. Teams without sufficient firmware experience often underestimate the complexity, leading to unstable behavior, delays, and costly debugging later in the process.

Ideally, your team should include developers with a background in firmware for similar devices – or a trusted external partner. They can help anticipate critical details early and build a stable, scalable architecture from the start.

Pro Insight: Firmware doesn’t tolerate guesswork. Even the simplest-looking device needs experienced hands to ensure reliable performance, security, and readiness for future updates.

Final Thoughts

Effectively managing custom software development for consumer electronics takes more than solid specs and agile sprints. It’s about anticipating what happens after the firmware ships-how it behaves in unpredictable real-world environments, how it adapts to hardware revisions, and how it supports users and manufacturers alike over time.

The most successful projects don’t just deliver features-they deliver resilience. That means designing for diagnostics, manufacturing constraints, future updates, and hardware volatility from day one.

With over 15 years of experience building software and firmware for devices in audio, IoT, and peripherals, Developex helps teams de-risk development and accelerate product readiness-without sacrificing long-term stability.

Launching or scaling a CE product? Let’s talk about how we can support your next project-from architecture to post-launch updates. Explore our experience or reach out directly.